Case study: Maintenance Excellence in the North Sea

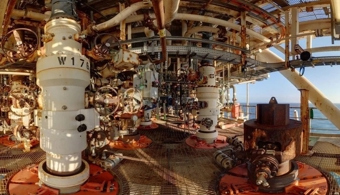

Facing the challenge of outdated site information and repeated maintenance visits, a North Sea super major adopted R2S to create a current digital replica of its North Sea assets. This shift enabled maintenance teams to spot discrepancies, plan tasks from onshore, and streamline scheduling. The impact was immediate, achieving $20 million in cost savings and reclaiming 75 man-years, all while improving safety and operational efficiency. With R2S, maintenance teams gain clarity, reduce site exposure, and deliver measurable results, making every maintenance campaign more effective and less disruptive.

Read James Fisher and Sons plc's latest Annual Report

Read James Fisher and Sons plc's latest Annual Report