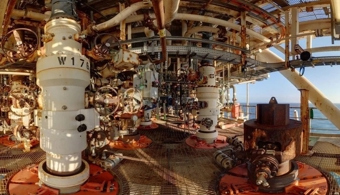

Case study: Transforming Turnarounds in the Gulf

A major operator in the Gulf faced the familiar challenges of turnaround season: hundreds of work packs, unfamiliar assets, and the logistical headache of getting the right people offshore at the right time. By adopting R2S, the team created a detailed, up-to-date digital view of the facility, allowing planners and contractors to scope work, identify hazards, and align on tasks, all before setting foot on site. This shift meant fewer offshore man-days, improved work pack accuracy, and a dramatic reduction in costly surprises. The results spoke for themselves: a 10% improvement in turnaround duration, over 1,000 offshore man-days saved, and $10 million in earlier production realised. With R2S, turnaround teams plan smarter, collaborate better, and deliver safer, more efficient TARs, making every shutdown less disruptive and more predictable.

Read James Fisher and Sons plc's latest Annual Report

Read James Fisher and Sons plc's latest Annual Report